Technology Exchange

Production is a very rigorous thing, Especially the production of industrial products is often time-consuming and expensive, so we should pay more attention to the quality of the finished product during the production process. Therefore, In order to increase the ductility and toughness of the weld and improve the quality of production, we need to heat the weld.

So what is post-weld heat treatment? Why is post-weld heat treatment imperative?

Post-weld heat treatment is the process used to eliminate the residual stress of the welded joint, improve the weld structure, and increase the toughness of the joint.

So what is the importance of post-weld heat treatment?

1. Eliminate welding residual stress

After the welding is completed, residual stress may appear. Therefore, in order to prevent deformation of the workpiece and improve the performance of wood and welded components, we need to use post-weld heat treatment to eliminate residual stress.

2. Reduce hardenability

After heat treatment after welding, the residual stress is reduced, the plasticity and toughness of the weldment are improved, and the hardenability is reduced.

3. Exhaust hydrogen

Hydrogen will cause the welded joint to be brittle during use. Therefore, it is very important to remove hydrogen. In the heat treatment process, the temperature rises and the hydrogen will overflow. When the heating temperature reaches 300℃ or less, the heat preservation can be used for 2-4 hours. Hydrogen, heating temperature between 550℃-650℃, can achieve hydrogen removal.

4. Anticorrosion

For stainless steel products, the residual stress of the welding structure will reduce the corrosion resistance of the material, and the post-weld heat treatment can remove the stress, which can play a role in corrosion protection.

At present, the post-weld heat treatment generally selects single high temperature tempering, normalizing and high temperature tempering treatment.

For gas welding joints, normalizing and high temperature tempering heat treatment are used. This is because the grains of the weld seam and heat-affected zone of gas welding are coarse, and the grains need to be refined, so normalizing treatment is adopted. However, single normalizing cannot eliminate residual stress, so high temperature tempering is required to eliminate stress.

A single medium-temperature tempering is only suitable for the assembly welding of large-scale ordinary low-carbon steel containers assembled on the site, in order to achieve partial elimination of residual stress and hydrogen removal. In most cases, a single high temperature tempering is used. The heating and cooling of the heat treatment should not be too fast, and strive to make the inner and outer walls uniform.

POLARIS-ETeK's heat treatment application

Preheating before welding and heat treatment after welding

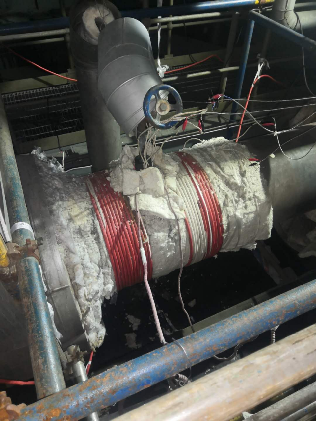

Insulating skeleton, winding magnet wire, quickly heating the whole roll

Semi-circular coil, preheating before welding with the rotation of the roller

|  |

Flexible cable, evenly wound on the roll to heat the roll

Heat treatment after welding

Choosing a suitable heat treatment process is conducive to achieving a better heat treatment effect. If you have any questions about post-weld heat treatment, you can consult POLARIS-ETeK.

Scan and follow!

Scan and follow!