Technology Exchange

Mold heating is widely used in life. For example, plastic molds are very common in life, children's toys, sewage pipes, etc., all need to be heated, because after heating, the quality of injection molded parts can be stabilized and the processing time can be optimized. Purpose.

Similarly in the industry, the application of mold heating is also very common, so why do you want to preheat the mold?

In order to protect the mold and improve the efficiency of the mold, it is very necessary to keep the working state of the mold within a certain temperature range as much as possible. If the mold is not preheated, on the one hand, due to the low mold temperature, it is easy to cause defects such as difficulty in molding, mucous film, casting cracks, and on the other hand, because the mold temperature changes too much, the hot and cold stress is large, and it is easy to cause damage to the mold. In severe cases, the mold may burst. Therefore, preheating of the mold before use is very important.

The picture below shows that the mold was not heated in advance, which caused the steel plate to crack.

At present, there are three common heating methods commonly used for mold preheating: electromagnetic induction heating, electric heating, and gas heating. In comparison, electromagnetic induction heating has the highest heating rate, high degree of automation, and environmental protection. It is currently the most commonly used heating method. If you want to know the detailed advantages and disadvantages of these three heating methods, you can refer to the article "The advantages and equipment advantages of intermediate frequency heating equipment compared with other heating methods"

Some actual cases of forging press die preheating made by POLARIS-ETeK are for your reference:

The forging press equipment used by a large state-owned enterprise mainly forges the diathermy bar material in the mold cavity to deform it to meet the subsequent process. (Before the forging press runs, the mold needs to be preheated, otherwise it will affect the demolding effect, and it is easy to damage the mold, crack or burst)

Process requirements: Before the forging press works, the entire cavity and the upper die need to be uniformly heated to 350°C.

Upper die of forging press

Lower mold cavity of forging press

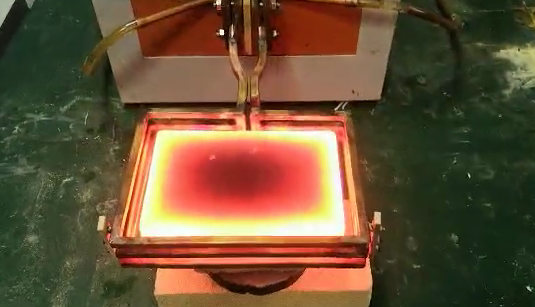

Mobile phone screen graphite mold heating

POLARIS-ETeK has been manufacturing induction heating equipment for more than 10 years. At present, all aspects of technology are relatively mature, especially in pre-weld preheating, post-weld heat treatment, smelting, and smelting. If you have any problems in this regard ,Welcome to consult.

Scan and follow!

Scan and follow!