Technology Exchange

Welding is widely used in life. Automobiles, air conditioners, aviation, nuclear industry, shipbuilding, construction, etc., are used most in industry, and with the development of China’s economy, welding technology has become an indispensable The processing means.

Pic1

This picture must be familiar to everyone. I remember that when I was a child, I could see it when I passed by the garage. Now I see it and it is very emotional. Sparks are splashing. Even if you hold the eye mask to block it, it will probably hurt your eyes.

But now, with the continuous advancement of science and technology, although this kind of manual welding can also be seen, because small workshops use more words, but in order to improve work efficiency and save costs, no cremation welding has appeared, and this kind of induction heating The most important point of this method is low cost and high efficiency. It is widely used in medium and large industries.

So what are the main advantages of induction heating?

1) Fast heating speed, not easy to deform;

2) Slightly oxidized;

3) High efficiency;

4) Automation;

5) Low production cost;

6) Safety and environmental protection;

7) Low technical requirements for workers

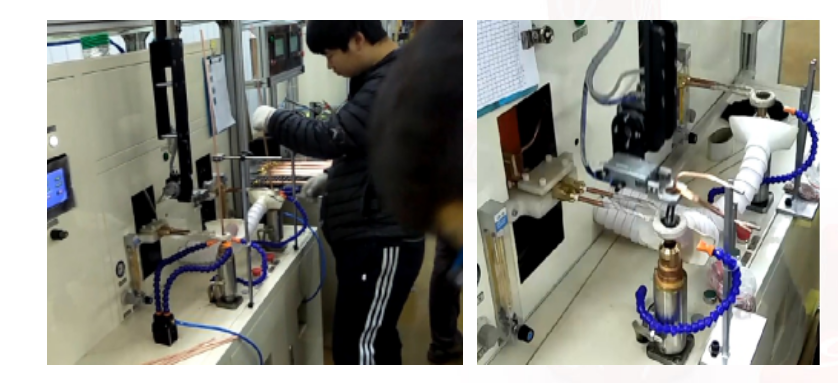

Pic2

The process of induction brazing:

Clamping -> Placing solder -> Soldering -> Cleaning

1. Workpiece Clamping

Don't look at just simple fixtures, but in order to ensure the welding effect, induction heating has four requirements for fixtures:

1) High positioning accuracy;

2) Simple operation;

3) Good thermal conductivity or heat insulation;

4) High degree of automation, reducing manual intervention.

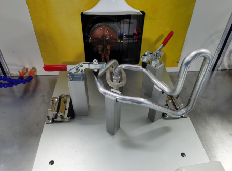

Pic3

2. Place the Solder

After the product is clamped, the solder can be placed. There are mainly two commonly used solder forms, 1.solder rings, 2.solder paste

3. Welding

After the solder is placed, it can be soldered. The welding process of induction brazing is fully automatic, and the operator only needs to press the start button to automatically perform welding.

4. Cleaning

During the welding process, there will be some slight scales or residues of additives. After the welding is completed, it can be cleaned by ultrasonic cleaning or chemical cleaning.

Application areas of induction brazing:

1、Air conditioning accessories

|  |  |

| Stop valve welding | Header welding | Welding of filter and drying bottle pipeline |

|  |

| Distributor welding | Solenoid valve welding |

2.Automobile air-conditioning pipeline assembly

Automotive air-conditioning pipeline welding

Automotive air-conditioning pipeline welding

Welding of evaporator lead pipe

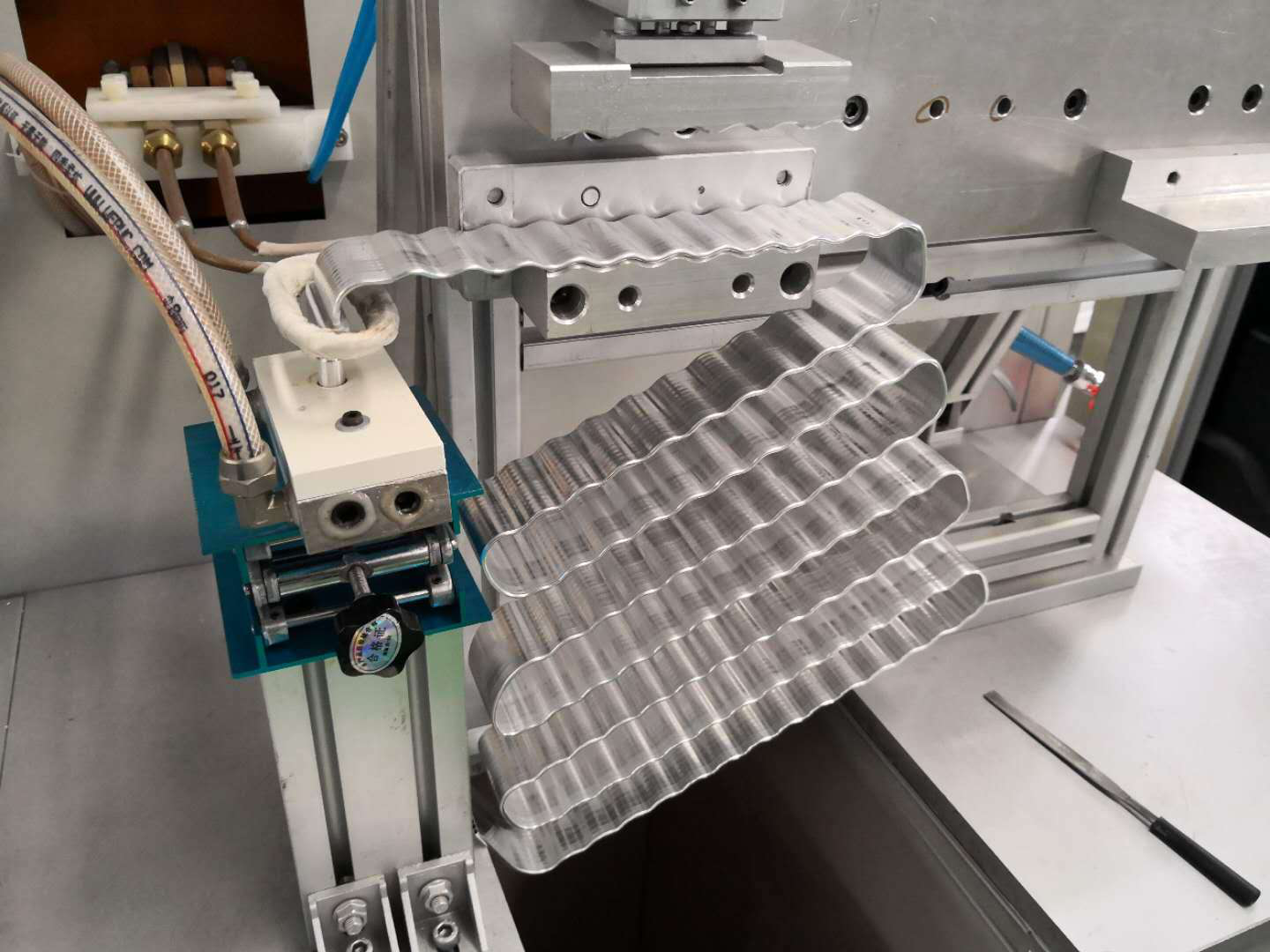

3. New energy vehicle battery pack water-cooling belt and water-cooling plate

Water cooling belt welding

Water cooling plate welding

FDA welding

Scan and follow!

Scan and follow!