Technology Exchange

For intermediate frequency electromagnetic induction heating, some people may only know this process, but they still don't understand the actual implementation. Today, Beichen Yike will show you the on-site implementation process of intermediate frequency electromagnetic induction heating.

Process steps:

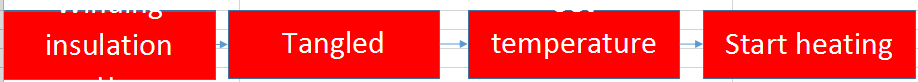

Pic1

Summarize:

The key steps of the implementation are the detection and control of entanglement and temperature

1. Twisting skills:

The winding position and density of the magnet wire will directly affect the heating effect. The denser the magnet wire is wound, the faster the heating will be;

2. Temperature detection:

The selection of temperature sensors, the number of temperature monitoring points, and temperature control algorithms are related to whether the entire heating process meets the process requirements, and plays a vital role in the effect of heat treatment.

3. Heating uniformity

Whether the heating is uniform or not will directly affect the effect of the workpiece after processing, and the uneven heating will cause uneven distribution of the stroke of the metal structure, resulting in failure to meet the processing requirements.

Advantage:

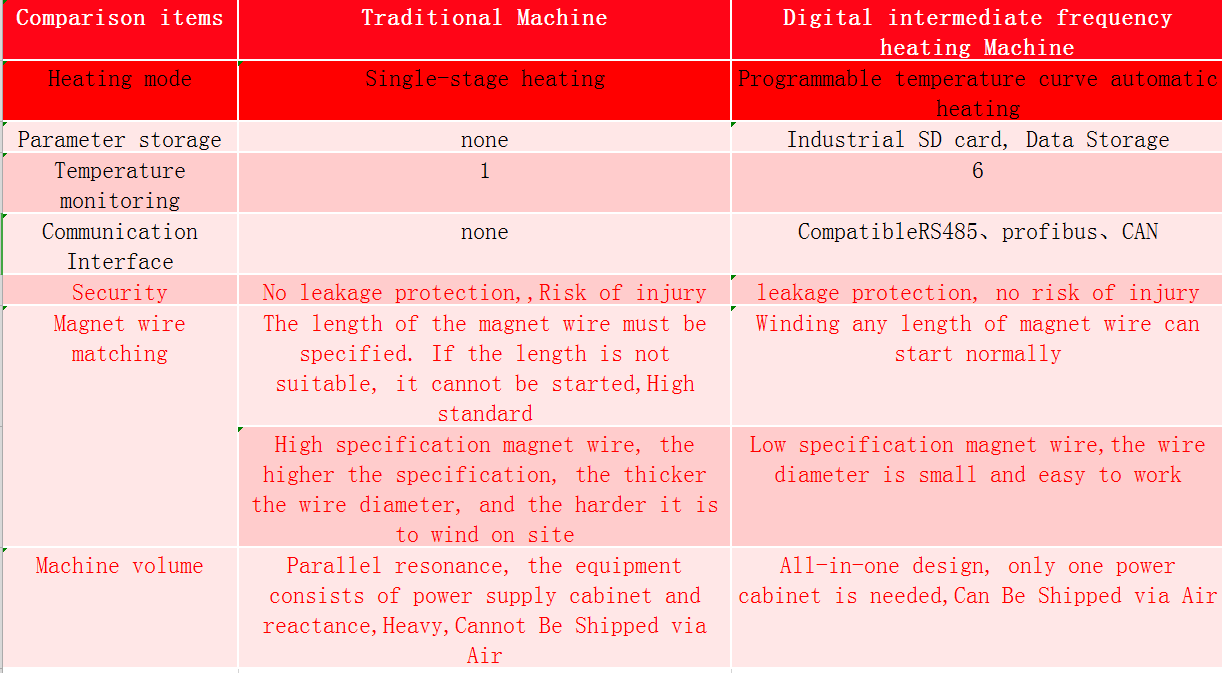

Comparison Intermediate frequency heating Machine with Traditional parallel resonanceheating Machine

Pic2

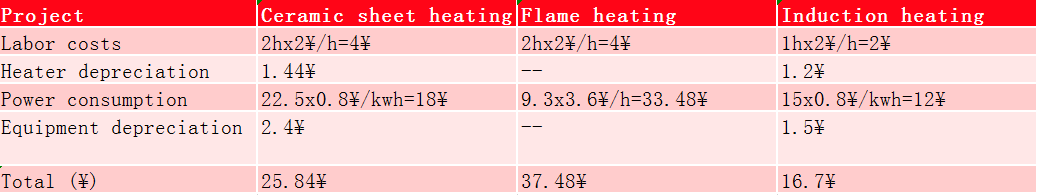

Comparison of the cost of intermediate frequency heating equipmentprocessing and traditional heating equipment

Pic3

Results:The cost of induction heating is about 65% of that of ceramic sheet heating and 45% of flame heating. Induction heating has the advantages of high efficiency and low cost Field case of medium .

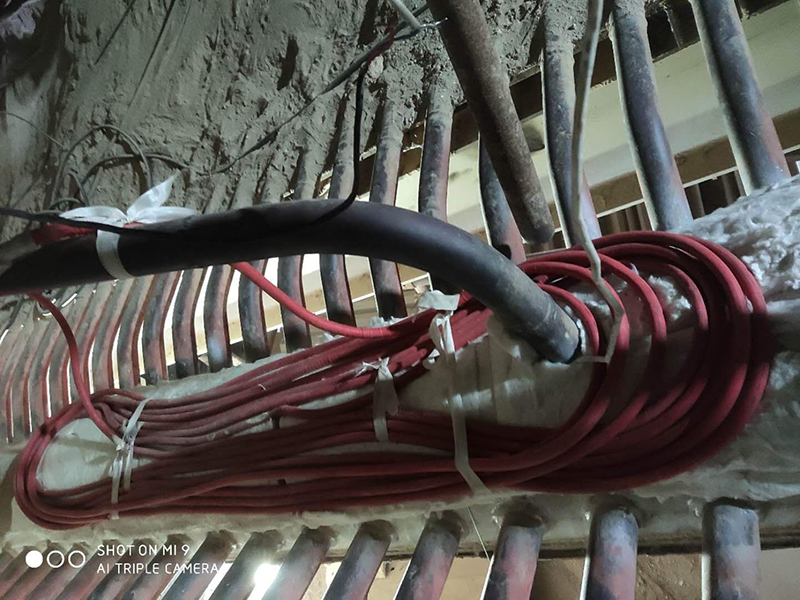

Frequency electromagnetic induction heating:

Pic4

Pic5

Pic6

If you have any questions about the above content, please leave a message.

Scan and follow!

Scan and follow!