Technology Exchange

What is preheating before welding?

Preheating before welding is a process measure to properly heat the weldment partly and as a whole before welding.

What is the purpose of preheating before welding?

The purpose of preheating before welding is to reduce the cooling rate of the welded joint, avoid the formation of hardened structure and reduce the welding stress and deformation, it is an effective method to prevent welding cracks.

What are the preheating methods before welding?

At present, the most commonly used preheating methods mainly include flame heating, ceramic sheet (resistance) heating, and induction heating.

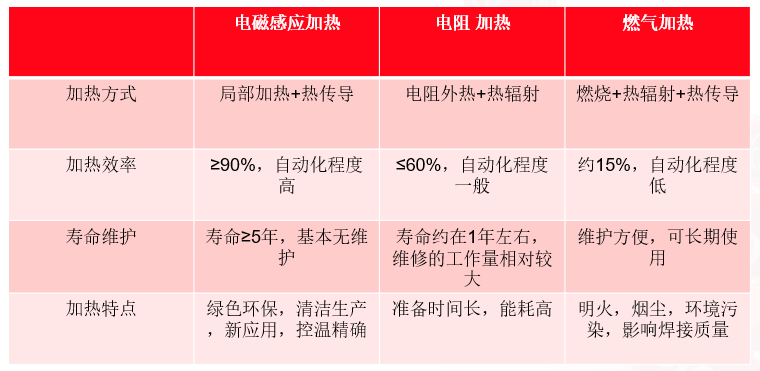

Comparison of the advantages and disadvantages of each preheating method

Advantages of medium frequency induction heating equipment

Energy saving: The energy utilization rate of induction heating is 40%-50% higher than that of ceramic sheets, and 50%-70% higher than that of flames, which has obvious energy-saving effects.

Fast heating speed: Under the same working conditions, induction heating is faster than ceramic sheet and flame heating. Induction heating does not burn out the oxide scale on the surface of the workpiece, saving materials and costs.

High degree of automation: induction heating can carry out real-time and precise automatic temperature control according to the current temperature status of the heated workpiece. The output power of the power supply can be adjusted in real time through the temperature closed-loop control system, so that the heating temperature or distribution of the workpiece can be automatically adjusted.

Improve and protect the environment: induction heating does not produce exhaust gas or smoke, low external heat radiation under heat preservation conditions, low noise, green working environment, and low labor intensity of operators.

Safe and reliable: Induction heating does not produce open flames, preventing the possibility of fires, explosions and other dangerous events, and the safety is greatly improved.

Easy to use: The main body of the induction heating device is an inverter induction heating power supply with semiconductor power components as the core structure. It does not need to be preheated and can be turned on and off at any time. Due to this feature, not only is it easy to use and operate, but it also saves time and energy.

Small installation site area: The induction heating power supply has a compact structure, and its composition is almost a modular and standardized component composition method. The mass and volume are relatively small compared to ceramic sheets and flames. The equipment installation area and space are small, saving space and infrastructure. cost.

Local heating can be carried out: the workpiece can be locally heated to replace the overall heating of the workpiece, the process is flexible, and the heating time and cost can be saved.

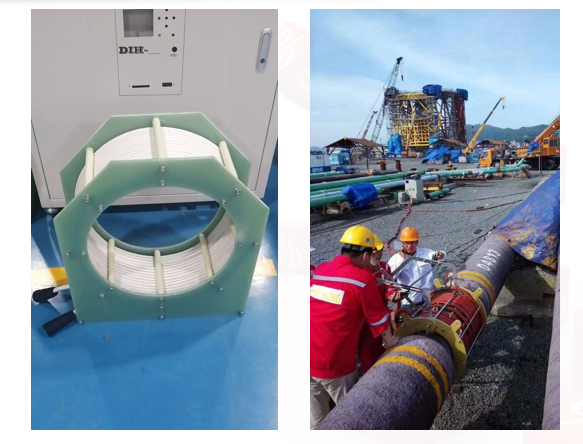

Field case:

Scan and follow!

Scan and follow!