Technology Exchange

Concrete pump tube quenching

1. Overview of the quenching equipment for the inner wall of the concrete pump tube and the quenching equipment for the concrete pump tube:

The quality and service life of the concrete pump tube is one of the keys depends on the accuracy of the inner wall of the concrete pump tube and the quenching process requirements. The concrete pump tube is made of steel pipe of special material. After inner wall quenching and carburizing chemical treatment, the hardness of the flange bushing reaches 58-60 degrees, and the service life of the pipeline is increased by 3-5 times, which saves the user time and expense. The trouble of frequent replacement improves production efficiency. The performance and life of the unquenched concrete pump tube and the quenched concrete pump tube are different. The quenched concrete pump tube can transport nearly 10,000 cubic meters of concrete.

2. The main technical parameters and processes of the quenching equipment for the inner wall of the concrete pump tube and the quenching equipment for the concrete pump tube:

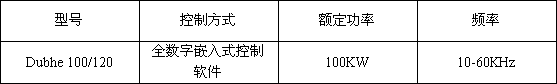

Using our company's pump tube inner wall quenching equipment, the inner wall of the Φ125-Φ200 concrete pump tube can be quenched successfully. The main technical parameters are as follows:

The quenching adopts a low-loss, high-insulation coaxial structure, and the length of the quenched concrete pipe is within 3,500. The inter-electrode withstand voltage of the sensor is 3000V. The induction front end adopts a quick-connect type, which is convenient for customers to use.

The technical instructions reached by the quenching equipment for the inner wall of the pump tube: quenching hardness: HRC55, quenching travel speed: 300-400mm per minute, 3 meters of concrete pipe takes about 10 minutes. Depth of hardened layer: 1.5-1.8mm, quenching water temperature lower than 45℃.

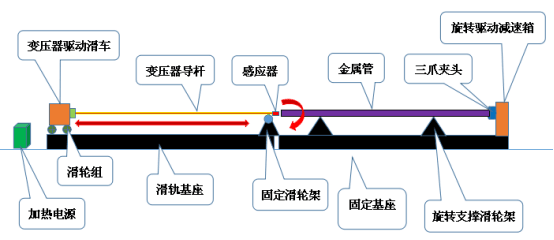

Auxiliary equipment for quenching equipment for the inner wall of the pump tube: To quench the concrete tube, there are two movements:

1. The first one is rotation: the purpose is to quench evenly. For example, there is a slight difference between the junction of the two poles of the sensor and the surrounding area of the sensor. After the top is sprayed with water, the water will flow down immediately. While the lower part is always immersed in water, all these factors are solved by rotation.

Rotation speed: about 120 rpm, which is too low to meet the requirements. It is easy to cause tremor if it is too high (the straightness of the tube itself is not too high). Need stepless speed regulation.

2. The concrete pipe advances and retreats along the axis. The advancement is for quenching, the speed is 100mm-500mm/min, the axial stroke is 4000mm, and the speed is stepless. It has the function of fast retreat, the speed is about 3000mm per minute, and stepless speed regulation is required.

3, the characteristics of concrete pump tube quenching equipment:

1. The frequency of the equipment can be based on the requirements of the workpiece processed by the user, generally 25-35KHZ, the suitable hardness is 2-4mm, and the quenching hardness meets the requirements.

2, the speed is 1/3 faster than the intermediate frequency, there is no whistling noise of the thyristor intermediate frequency, and the deformation is small.

3. The inductor has fine workmanship and is specially used for the coaxial water-cooling structure for quenching the inner wall of the concrete pump tube.

4. Using German Siemens IGBT power tube and unique inverter technology, the efficiency is 30%-40% higher than the old-fashioned thyristor intermediate frequency, and the power saving is 30%-40%.

5. Using digital control system, heating temperature is more accurate.

6. High power factor has low pollution to the power grid.

7. This equipment complies with the internationally accepted 3S standards (SURE reliable, SAFE safety, SAVING saving), and 3C standards (COOL low temperature, CLEAN clean, CLAM quiet).

8. It comes with a digital communication output interface to facilitate joint control with external related equipment to realize automatic operation of the production line.

Scan and follow!

Scan and follow!