Technology Exchange

Stator hot charging

Stator sleeve hot sleeve

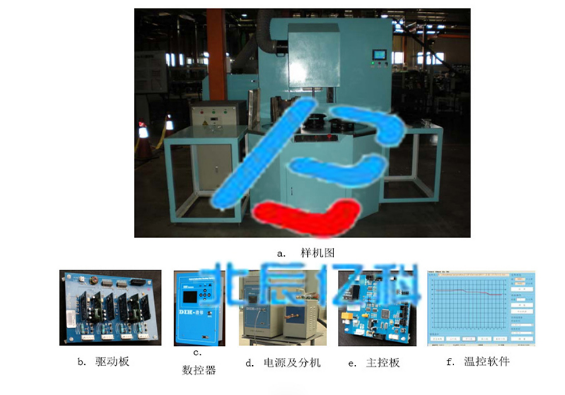

Abstract: The article mainly introduces the special automatic heating equipment and its components specially customized by our company for a well-known international company. According to the requirements of customers, the characteristics and advantages of the stator sleeve heating equipment developed by our company.

Keywords: stator sleeve thermal jacket, thermal charging, heating equipment, induction heating.

1. Introduction of stator jacket heating equipment

The stator sleeve heating equipment is a special automatic heating equipment specially customized by our company for a well-known international company. It is mainly used for the heating process before the thermal assembly of the motor stator sleeve. This equipment is composed of induction heating part, workpiece conveying and rotating part, sensor lifting part, infrared temperature monitoring part, cooling cycle part and electrical control part.

2. Equipment requirements

(1) The overall temperature of the workpiece is required to reach 203~213℃.

(2) Operator loading and unloading at different stations on the equipment.

(3) The stator sleeves of various specifications are heated by uniform specifications of the inductor, which reduces equipment preparation time and improves production efficiency.

(4) The working cycle of the equipment (including loading and unloading of workpieces) does not exceed 3 minutes.

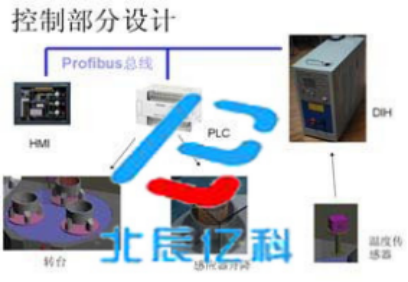

(5) Use an infrared thermometer to accurately measure the temperature of the stator sleeve, and submit the real-time temperature data to the PLC and heating controller for precise temperature control;

3. Equipment characteristics

(1) Use an infrared thermometer to accurately measure the temperature of the stator sleeve, and submit the real-time temperature data to the PLC and heating controller for precise temperature control;

(2) Based on the latest DSP control technology, the power can be output according to the multi-stage temperature curve,

It can realize the control of the preheating stage, the diathermy stage, and the heat preservation stage to ensure the uniform heat transmission of the entire stator sleeve.

(3) The induction heating equipment has functions such as current control, data recording and alarm recording, and is designed with communication methods such as RS485, which can be easily connected to PLC control to realize the automatic production and processing and fault diagnosis of the whole machine. All heating data are recorded in real time and can be used to save or submit.

Scan and follow!

Scan and follow!