Technology Exchange

Induction brazing of electrical connectors in the communications industry

1. The working principle and characteristics of induction brazing

The brazing of electrical connectors is mainly used for welding electrical connector products, which are the replacement products of the old "P" type electrical connectors (aviation plugs), which are small in size, light in weight, easy to use, resistant to plugging, and good electrical conductivity. Features of good airtightness. It is widely used in wiring connections between various electrical equipment, instruments and meters. Because electrical connectors have relatively high technical requirements for accuracy, air tightness, and weld flatness after welding, the application of electrical connector brazing technology has high requirements for induction brazing equipment.

Current electrical connector welding generally includes: vacuum brazing, reflow soldering, and hot plate welding; the above welding methods are prone to excessive heating time, excessive "sophistication", oxidation, or uncontrollable heating temperature, which may cause the performance of the workpiece to decrease or Cause irreversible damage to the workpiece. In addition, multi-chip microwave components often contain a large number of electrical connectors that need to be soldered. The connectors have high distribution density and large differences in shape and structure. It is difficult for ordinary soldering techniques to achieve high soldering efficiency and high reliability. All companies are seeking technological innovation, and mastering a new welding method means mastering the market. Induction brazing technology can well overcome these shortcomings, and the emergence of induction brazing provides a brand new method for technological innovation.

Induction brazing is a welding method that uses high-frequency, intermediate-frequency or power-frequency induction current as a heat source. The main principle of induction nail welding technology is to rely on the workpiece to generate induction current in the alternating magnetic field of alternating current and then generate resistance heat to heat, so it can realize rapid heating and cooling, high welding efficiency, less solder oxidation, and can control the heat in the workpiece welding The local part has a small heat-affected area, which avoids the additional influence on the components of other parts.

According to its technical principle, the advantages of induction brazing technology:

(1) Since the heat is generated by the workpiece itself, it is heated quickly, and the oxidation of the workpiece surface is much less than that of brazing in the furnace, and it can prevent the growth of the grains of the base material and the development of recrystallization.

(2) Due to the skin effect of induction heating, local heating of the workpiece can be realized, and the high degree of heat localization can make the solder joints quickly reach the required temperature for melting without risking damage to the workpiece.

(3) Since induction heating brazing adopts a heating method from the inside out, its effect is not affected by the change of the brazing position or the joint.

(4) Induction heating can achieve rapid heating and cooling, often in a few seconds, and the welding cycle is faster, which improves production efficiency and is very suitable for automated and large-scale production processes.

At present, induction heating technology is widely used in various metals, including aluminum, pure copper, copper alloy, iron, cast iron, stainless steel and other weldments with symmetrical shapes. It is especially suitable for the socket connection of pipe fittings, pipes and flanges, and shafts. Connection with similar joints such as shaft sleeves.

Induction heating technology has a significant feature-skin effect. We call the current induced by the alternating magnetic field in the workpiece as eddy current. Due to the existence of the skin effect, the eddy current will decay exponentially along the surface of the cross-sectional towel to the inner layer, so the distribution of eddy current is not uniform, the maximum current The density appears in the surface layer of the conductor. Engineering stipulates that when the eddy current intensity decreases from the surface to the inner layer to a total value equal to 1/e (ie 36.8%) of the maximum eddy current intensity, the distance 6 from the surface to the surface is called the current penetration depth. Since the electric heat is proportional to the square of the current, the heat decline rate from the surface to the inner layer is much faster than that of the eddy current. It can be considered that 85%-90% of the heat is generated in a thin layer of thickness. The penetration depth is inversely proportional to the square root of the material's electrical conductivity, relative permeability, and frequency product. The existence of the penetration depth can make the heat generate white parts of the workpiece without affecting other devices, but the penetration depth is not as small as possible. First, because the penetration depth is too small, electromagnetic waves will be reflected on the metal surface, which will reduce the electrical efficiency; second, when the metal surface heats up, because the surface will radiate heat at the same time, when the heat dissipation is large or even greater than the heat conducted to the inside of the workpiece The thermal scene of the area, which affects the overall thermal efficiency. Therefore, according to actual engineering requirements, materials with moderate permeability and electrical conductivity should be selected, and they should not be large or too small. In this paper, according to the technical characteristics of the above-mentioned induction brazing, the technology is applied to the brazing of electrical connectors. The article mainly introduces the main factors of induction nail welding process design, such as workpiece structure, workpiece material, contact coating, solder type, etc., and its influence on coil design and power setting during induction heating. Finally, the induction brazing welding applications of related electrical connectors are specifically listed in order to obtain microwave components with good welding quality.

2. Practical application of induction brazing

Combined with engineering examples, the process design of induction brazing electrical connectors is studied from four aspects: work piece structure, work piece material, contact coating and solder type for the main factors that affect the power setting and induction coil design.

1. Workpiece structure and coil design

The structure of the workpiece mainly refers to the shape and size of the workpiece and the shape of the mounting hole of the connector on the workpiece. It mainly determines the structural design of the induction coil and the difficulty of the entire welding process.

2. The influence of workpiece material

At present, common electronic packaging shells and workpiece materials mainly include titanium alloy, aluminum alloy, Al-Si, AI-SiC, Kovar, steel, and copper. These materials are used in different occasions in the field of electronic packaging according to performance indicators. , Table 1 lists the main physical properties of the first four materials. Therefore, when workpieces made of these materials are welded to electrical connectors using induction brazing technology, according to the characteristics of induction brazing described above, the skin effect of these materials is not exactly the same. Among them, the electrical conductivity and relative permeability of the materials The smaller the rate, the weaker the skin effect; on the contrary, the more significant the skin effect. For non-magnetic metal materials, because the permeability is small (constant 1) and has nothing to do with temperature, the skin effect is weak, and the resistance heat can be distributed in the deeper part of the I part, and the heating is more uniform; and for the relative permeability For metals with a rate greater than 1 (such as Kovar), the skin effect is much more pronounced. At the same time, in the process of induction heating, the conductivity of most metals will decrease as the temperature rises, and the machine-pair permeability will change due to the presence of hysteresis, and the material will approach paramagnetic after the temperature exceeds the Curie point. . Therefore, during induction brazing, it is necessary to set the power of the induction generator according to the temperature distribution characteristics of the workpiece to achieve sufficient effective power to meet the welding quality requirements. During induction heating, metal will dissipate externally and internally in the form of radiation and heat conduction. Because different metals have different thermal conductivity, the greater the thermal conductivity, the faster the heat conduction, so the power setting of the induction generator must also be considered The influence of thermal conductivity, the metal with low thermal conductivity, the power setting of the induction generator is relatively increased.

3. The influence of precise temperature control

Our company's induction heating equipment adopts multi-stage heating settings and has a heat preservation mode. During the heating process, infrared thermometers or other equipment can be connected to the heating equipment to achieve the purpose of automatic heating and ensure the accuracy of the heating temperature and heating process. Because the traditional high-frequency machine uses analog quantity for control, and thermometers and other equipment generally use digital signals for data transmission. Due to the different communication methods, there will be a "transmission" process, and the existence of this process will cause serious delays. Even if the equipment is matched with the infrared temperature measuring equipment and the digital signal is converted into an analog signal, the hysteresis will still be very serious due to the low control accuracy and resolution. However, during the machining process, the machining accuracy will be greatly reduced, and the hysteresis phenomenon is to a large extent the cause of the machining failure. During the heating process, the heating temperature has a great influence on the welding strength, air tightness, oxidation degree and the physical properties of the workpiece itself, which may affect the success or failure of the welding.

4. The impact of high reliability design on welding

When welding, the reliability of the equipment has a direct impact on the heating process and results. All products of the company have digital control as the core. Because we always believe that digital technology can enable production activities to achieve automation, precision, standardization, reproducibility and data traceability. We can only speak with data! When using analog induction heating equipment for welding, due to the limitations of its control method, the welding parameters of different personnel and different times are not the same. Therefore, the use of analog induction heating equipment for mass production of the same product will not be able to meet the requirements of welding consistency. The intelligent brazing system is controlled by digital embedded software. The processing parameters can be accurate to 1A and the processing time can be accurate to 0.1 seconds. All processing parameters can be stored in the SD card in real time, which is convenient for data retrieval and big data analysis. Therefore, the intelligent welding system guarantees the welding consistency of the product!

5. The influence of contact coating

The surface of the workpiece and the connector is usually coated with a thin metal coating, which can be between 0.4-3.5 μm according to its different functions. These coatings mainly play the role of avoiding corrosion and optimizing the contact interface. According to the types of contact coatings, it is divided into two categories: precious metal coatings and ordinary metal coatings. Noble metal coatings include gold, palladium and their alloy materials, while ordinary metal coatings include silver, nickel, tin and tin alloys. These metals have different weldability and anti-corrosion properties and need to be selected according to engineering design requirements. For example, the inert precious metal Au, not only has quite good electrical and thermal conductivity, but also has good corrosion resistance in almost any environment. sex. At the same time, the gold plating layer can optimize the contact interface, so that the metal interface with poor solderability becomes good wetting. Although the silver plating layer also has good solderability, it has the defects of migration and discoloration, and is not suitable for exposure to air and moisture. In the induction brazing process, it is particularly necessary to pay attention to the solderability of the contact coating and the reliability of the coating quality. The higher the solderability level, the foundation for the formation of reliable solder joints. In induction welding, the most basic requirement is: the power is set appropriately, the solder is completely melted to form a good solder joint, and the contact coating does not bubble or change color when heated.

6. Selection of solder

The appearance quality of induction brazed connectors requires the solder to fill the gap, the weld is full, and the exposed end of the brazing to form a uniform fillet, etc., which puts forward requirements for the selection of solder. The heating cycle of induction brazing is generally relatively short, ranging from a few minutes to a few seconds to complete the entire heating process, so that the solder is completely melted, the flux is volatilized, and the solder is evenly distributed. In engineering applications, it is found that when using solder paste flux, due to the large amount of organic matter in the solder paste, it is difficult to oxidize and volatilize in a short time, and bubbles will be generated during volatilization, and the solder will splash, resulting in the result shown in Figure 5A The extremely small tin bead spatter, so it is considered that the welding sound is not suitable for large-scale use in the induction brazing process. When using soldering pads, due to the need to dip more flux, excess flux may remain in the gap after soldering, and it is not easy to clean. Therefore, it is considered that the soldering pads that are not easy to wet are not suitable for large-scale use in induction brazing. Craft towel. Therefore, in induction brazing, in order to make the appearance quality inspection after welding meet the design requirements, such as smooth surface and full gap filling, the selection of solder is very important. For the selection of solder compound types, the main consideration is the solder melting temperature requirement, which conforms to the temperature gradient design. In order to form a uniform fillet at the weld and prevent the solder from flowing out, it is necessary to select a solder with a proper wetting angle and surface tension.

|

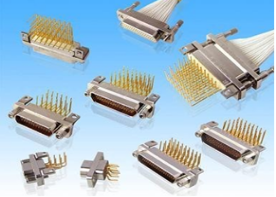

| Figure 1 Connector (round) |

At present, induction heating technology is widely used in various metals, including aluminum, pure copper, copper alloy, iron, cast iron, stainless steel and other welded parts with symmetrical shapes. It is especially suitable for the socket connection of pipe fittings, pipes and flanges, shafts and Connections in the form of shaft sleeves and similar joints. For example, induction heating welding of large components such as pipe joints that need to be disassembled on rockets is used for welding of inner conductors of coaxial microstrip lines. Now, by using more precise induction coils, non-contact temperature measurement technology, and more precise wire feeding and filler forming, induction heating brazing technology can be used to weld various small parts\components, such as radar microwave components.

|

| Figure 2 Connector (rectangular) |

As the microwave components include a large number of substrates, MMICs, and bare chips, etc., in order to ensure the stability of performance when assembling and soldering each part, a reasonable temperature shave must be controlled to prevent each part from interfering with each other. In order to ensure the long-term and reliable operation of microwave components, high requirements are put forward for the packaging and welding of electrical connectors connected to the outside, such as air-tight welding, low-temperature welding, and mechanical stability requirements. The traditional low-temperature brazing methods for electrical connectors are mainly vacuum brazing, reflow soldering, hot plate welding, etc. Although the vacuum brazing process can overcome the high temperature oxidation defects of the solder in the reflow soldering and hot plate soldering processes, they They all heat the entire component and the heating time is long, which will cause secondary heating to other components on the component. However, the induction brazing process can well overcome these defects. According to the advantages of induction brazing, it can be heated and cooled quickly, so the solder is less oxidized and the welding efficiency is high; and the heat can be controlled at the local welding part of the workpiece to avoid It also affects the heating of other parts and components.

|  |  |

| Figure 3 Other types of plug-ins | ||

| ||

| Figure 4 All-digital high-frequency brazing power supply | ||

| ||

Figure 5 Welding state diagram | ||

3. Quality inspection after induction brazing

Excellent electrical connector welding parts can not only play the role of mechanical support and signal transmission, but also need to meet the air tightness of the package and the effect of shielding external electromagnetic interference. This article uses induction brazing technology to weld two different forms of electrical connectors. The transmission characteristics and electromagnetic shielding characteristics of the connector are mainly determined at the factory. For the brazing process, the mechanical stability and air tightness of the connector need to be determined. Test to evaluate the actual effect of induction brazing technology in the welding of electrical connectors. According to the design requirements, appearance inspection, internal defect inspection and air tightness index inspection were carried out.

1. Appearance inspection

The appearance inspection is to check the surface quality of the brazed joint with a low-power magnifying glass, such as whether the solder fills the gap, whether the exposed end of the brazing seam is rounded, whether the rounded corners are uniform, whether the surface is smooth, whether there are cracks, pores and other external parts Defects, etc.

2. Internal defect detection

X-rays are used to detect internal defects in welding. X-rays are a common method to inspect internal defects of important workpieces. It can show pores, slag inclusions, incomplete penetration, and cracks in brazing seams and base materials. Due to the small size of the connector, we evaluate its internal welding quality through the level of penetration rate. The assembly gap between the connector and the workpiece is completely brazed, without porosity, and the solder is completely spread.

3. Air tightness index detection

Commonly used methods for airtightness index detection include general hydraulic test, airtight test, kerosene penetration test and mass spectrometry test. Among them, the hydraulic test is used for high-pressure vessels, the air tightness test and the gas permeation test are used for low-pressure vessels, the kerosene permeation test is used for pressure-free vessels, and the mass spectrometry test is used for vacuum sealed joints. According to the method 1014.2 specified by GJB548B, we use a mass spectrometer leak detector to detect the air-tightness index of the workpiece with the welded connector. The results show that the helium leak rate of all induction brazed connector joints (detected by helium mass spectrometer leak detector) is excellent At 5X 10-9(Pa/m�)*s(helium), it meets the design requirements.

4, the conclusion

The electrical connection on the microwave component was welded by induction brazing technology. The induction coil was designed to match the shape and size of the workpiece. The parameters of the brazing process were studied, and the induction frequency, coil and workpiece were optimized. Coupling and heating power parameters. The welding quality of the workpiece welded with the electrical connector finally obtained is good, and the weld seam is full, smooth, and void-free; X-ray inspection results show that the assembly gap between the connector and the workpiece is completely brazed, without pores, and the solder is completely spread. Helium leak rate better than 5X 10-9(Pa/m�)*s. This induction brazing technology is used to weld the microwave components of the connector, and it has been applied to a certain type of radar transceiver antenna system. This brazing technology is widely used in the welding of similar connectors. Induction brazing technology can realize the rapid welding of microwave electrical connectors, with less solder oxidation during welding, high welding efficiency, and the heat can be controlled at the local welding part of the workpiece. In view of the skin effect characteristics of induction brazing technology, the factors that affect the process design of the electrical connector during welding: the structure of the workpiece, the workpiece material, the contact coating and the type of solder have been studied. Among them, the structure of the workpiece determines the structure design of the induction coil and the difficulty of the entire welding process. We have designed the electrical connector mounting holes from both the boss design and the assembly gap design; and the material of the workpiece is due to the collection. The skin effect directly determines the power setting during induction brazing; finally, for the selection of contact plating and solder types, we propose to form solder joints and welds with good welding quality, and the contact plating will not bubble after welding. , Do not change color as the standard for process design. Guided by the above process design, the electrical connectors obtained by induction brazing can meet the relevant quality requirements and have excellent air-tightness indicators. Has a strong promotion value.

Our company's equipment has passed IOS 9001 certification and CE certification, etc., and has more than 20 industry patents. We are a very professional manufacturer of digital induction heating equipment. Each equipment will be fully tested by professional engineers before leaving the factory, and will be tracked to the customer's application site to carry out on-site technical debugging and process parameter transfer to ensure that the customer is in use. The technology and process parameters in, provide guarantee for the customer's full production cycle.

The company's production equipment application industry involves various industries and fields such as aerospace, machinery manufacturing, medical equipment, hardware and electrical machinery, refrigeration, heating and ventilation. "Science and technology innovation" is the soul of our enterprise, and "frank passion" is our driving force. We hope that the services and products of "Beichen Yike" can contribute to the development of your enterprise.

Scan and follow!

Scan and follow!