Produts

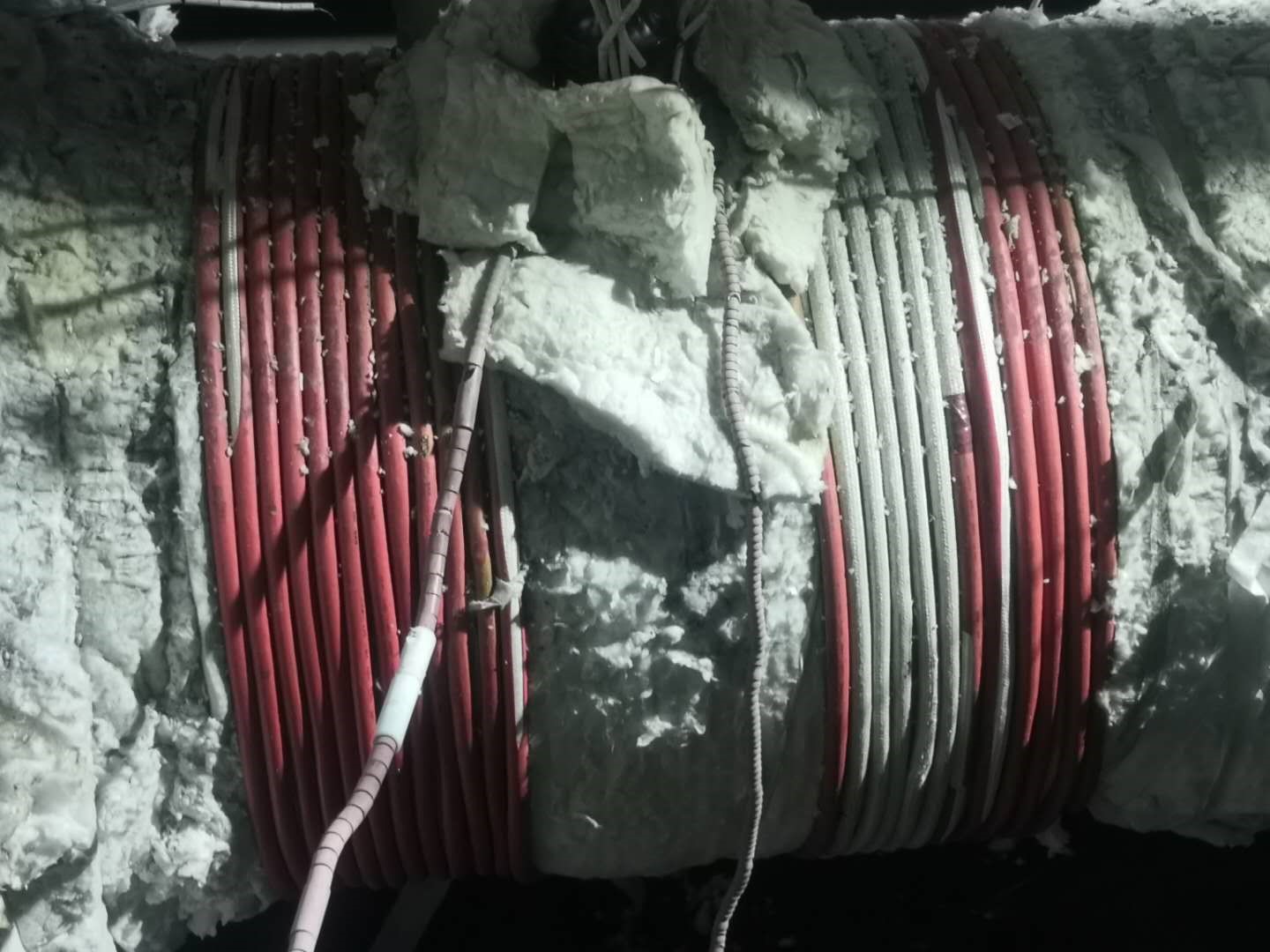

Pipeline Preheating/Post-Welding Heat Treatment Machine

Equipment Power:16kw-200kw

Oscillation Frequency: 10-20KHZ

Control Mode: Digital

Delivery Time: 3-20 days after confirming order,detail delivery date should be decided according to production season,order quantity and destination.

Warranty: 12 Months

Online Inquiry

-

-

Equipment introduction

Pipeline Preheating/Post-Welding Heat Treatment Machine

Features of Pipeline Preheating Machine:

1)Multi-stage temperature control (default 5 stages,Customizable)

2)The heating time can be accurate to 0.1S, and the heating current is accurate to 1A

3)Support parameter storage, which can be recalled on a computer and other equipment with one key

4)Abundant communication interfaces, which can be connected to industrial buses such as RS-485, profibus, CAN, etc.

5)Multiple operation modes are available, including manual mode, automatic mode, and temperature control mode

6)Real-time display of processing parameters, drawing of current and frequency curves, more intelligent

7)Interactive man-machine interface

Technical Parameters:Product Name

Digital Induction Heating Machine

Control Mode

Digital

Operating Mode

Manual Mode、Automatic Mode、Temperature Control Mode

Number of Heating Current Settings

5-32 segments

Number of Workpiece Parameters Sto

10 group

Work Status Display

Time、Current、Frequency、Current Time Curve

Alarm Interface

Lack of water、over current、over voltage、lack of phase、over current of the drive board, abnormal load、out of control,etc

Model Number

DIH-25

DIH-40

DIH-60

DIH-120

DIH-160

DIH-320

Output Power

16KW

25KW

40KW

80KW

100KW

200KW

0utput Frequency

10-60KHz

Main Extension Cable

2m

Input Voltage

380V士10%

Input Frequency

50/60Hz

Power Factor

0.93

Maximum Temp of Inlet Water

<35℃

Cooling Water Flow

12.5-17L/min

Host Size

530*255*520

595*305*520

480*570*720

535*775*970

635*800*970

760*620*980

Extension Size

380*270*280

470*360*380

820*400*370

990*510*990

990*510*990

1200*550*660

Application of Pipeline Preheating Machine:

1)Welding

Welding of various diamond composite drill bits, welding of various hard alloy cutter bits, saw blades, various pick bits, drill pipes, coal mine bits, air drill bits and other mining machinery accessories.

Welding of air conditioning and refrigeration accessories such as: high-frequency brazing of pipe joints, distributors, distributor tail pipes, sight glasses, four-way valve end caps, flute tubes, liquid storage bottles, drying bottles, shut-off valves and other workpieces.

Welding of automotive air-conditioning refrigeration accessories such as: high-frequency brazing of evaporator outlet pipes, single-tube pressure plates, double-tube pressure plates, air-conditioning pipes, sight glasses, parallel flow microchannel flat pipe joints, aluminum distributors and other accessories.

Welding of water-cooled belt joints, cold plates and other accessories in the cooling system of the power battery pack of new energy vehicles.

2)Quenching

Quenching of gears, sprockets, shafts, hardware tools, machine tool guides, and auto parts.

3)Other Uses

Metal smelting, heat-through forging, curing bonding, thermal assembly, heat treatment, pre-heating before welding, post-heating, straightening and leveling.

Partners

Tags:

Digital Induction Heating Machine Portable Induction Heating Machine

Scan and follow!

Scan and follow!