Produts

200kw Medium frequency Diathermy furnace

Melting Material: brass, high silver;

Workpiece size: φ46-60, length 60-100;

Heating temperature 250-350℃, small temperature deviation;

Heating cycle: 36-60s;

Equipped with feeder, cooling equipment, and manual material removal at the back end."

Online Inquiry

-

Equipment introduction

200kw Medium frequency Diathermy furnace

Process Flow:

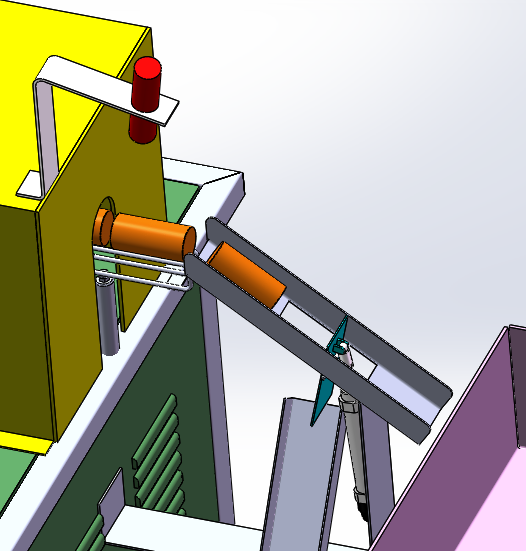

Technological process: the feeding mechanism sends the product to the conveyor belt → the conveyor belt rotates to transfer the product to the waiting area → the cylinder pushes the spindle to the feeding area → the cylinder pushes the spindle to the inside of the heating coil → automatic induction heating → the cylinder pushes the unheated product and will be heated product ejection.

Overall Design:

This system is used for Induction Heating of spindles and bars, equipped with a complete set of automatic heating equipment, including: induction heating part, electrical control and protection part, mechanical part, temperature control part and cooling part.

The induction heating part mainly includes a full-digital induction heating power supply and a diathermy furnace, which inductively heats the spindle to make it reach a predetermined temperature; the electrical control and protection part uses PLC and touch screen to realize the control and protection of the entire system; the mechanical part It mainly includes workpiece feeding and ejecting mechanism. The temperature control part mainly cooperates with the induction heating power supply to control the temperature of the workpiece in a closed loop to ensure the accuracy and consistency of temperature control. The cooling part is mainly used to cool the power supply and the induction coil in the diathermy furnace to ensure the normal operation of the equipment.

Process: Before heating, workers set the processing parameters on the touch screen, and start processing after confirming the save. Manually place a batch of products on the feeding mechanism, press the start button, the feeding mechanism will send the products to the conveyor belt, the conveyor belt will transport the products to the waiting area, the air cylinder will push the products to the feeding area, and the air cylinder will push the products to the feeding area. In the diathermy furnace, the induction heating power supply starts to heat, and the infrared probe monitors the temperature of the workpiece. After the temperature reaches the requirement, the next product will push out the product in the diathermy furnace, and this action is repeated.

Diathermy furnace description:

According to the process requirements, the same diathermy furnace is used for a variety of bars, so the inner diameter of the diathermy furnace is made according to the outer diameter of the largest workpiece, and the length is made according to the longest heating length. Insulation.

The inductor used in this system is a multi-turn spiral inductor. The coil is wound from a high-quality large-section whole rectangular copper tube, and the tube is cooled by water. In order to protect its insulation strength, the surface of the coil is coated with moisture-proof insulating paint and then solidified as a whole.

Screening Mechanism:

The infrared thermometer at the discharge port detects the temperature of the spindle at the discharge port. If the temperature of the spindle is too low or too high, the cylinder of the screening mechanism will lift the baffle on the slideway, and the unqualified spindle will fall from the gap of the baffle and pass through the guide mechanism. , falls into the unqualified product box, and waits for reheating. As shown in the figure, this institution is for program reference only.

Temperature Measurement Part:

The temperature control part mainly uses the infrared thermometer and the induction heating power source to carry out the temperature monitoring of the workpiece with its own digital program. When heating the end of the spindle, the infrared probe measures the temperature of a point on the end of the bar, and feeds back the temperature parameters to the induction heating power supply from time to time. Through the digital program of the power supply itself, the temperature control accuracy is ensured.

As shown in the figure below, the infrared temperature measurement probe is selected, and the infrared temperature measurement data is transmitted in the RS485 digital communication mode, and is directly connected with the high-frequency heating power supply through the DB9 connector, which is simple in connection and fast in response time.

Partners

Tags:

High Frequency Brazing Machine High-Frequency Welding of Household

Scan and follow!

Scan and follow!