Technology Exchange

Induction brazing of radiator

Abstract: This article proposes a high-frequency induction brazing method for radiators for single-tube pressing plates in automotive air-conditioning accessories. In addition, the process flow and operation method are proposed to improve the existing production process and solve the problem that the aluminum radiator is difficult to perform induction brazing.

Keywords: high frequency induction brazing, heat sink, aluminum high frequency induction brazing process

1. Overview of high frequency induction brazing of radiator

1.1 Overview of high frequency induction brazing

High-frequency induction brazing: The welding seam is heated to the melting temperature of the alloy solder by heating, but the metal being welded at this time still has not reached the melting temperature, and the low melting point alloy bonds the two metals together through strong surface tension After cooling, a solid weld is formed. The parts of the same or different materials can be welded together, the material saving effect is remarkable, and various needs can be met. Suitable for welding various magnetic materials such as steel, copper, aluminum, nickel, and special alloys. High-frequency local welding has high strength, no deformation, and comprehensive mechanical properties are better than other welding.

Shoulder brazing is one of many brazing methods. It does not use heat radiation to heat the metal, but uses the principle of electromagnetic induction to make the metal itself generate heat. This heating method has high energy utilization rate and rapid heating, and only uses electric energy, and has the characteristics of low energy consumption, low pollution, and low harm.

1.2 Overview of the radiator

The radiator is a device that accelerates the heat dissipation of the heating element. There are two points to measure the quality of a radiator: heat dissipation and silence. A large number of integrated circuits are used in computer components. As we all know, high temperature is the "big enemy" of integrated circuits. High temperature will not only cause unstable operation of the system, shorten the service life, and may even burn out some parts. The heat that causes high temperatures does not come from outside the computer, but inside the computer, or inside the integrated circuit.

The role of the radiator is to absorb the heat, and then radiate it to the inside or outside of the case to ensure that the temperature of the computer components is normal. Most radiators absorb heat by contacting the surface of the heating component, and then transfer the heat to a remote place through various methods, such as the air in the case, and then the case transfers the hot air to the outside of the case to complete the heat dissipation of the computer.

|

| Figure 1 Radiator |

2. Material welding performance analysis

Compared with other alloys, aluminum alloy is more difficult to braze, the main reasons are:

(1) It is easy to form an extremely dense oxide film on the surface. The nature of this oxide film is very stable, covering the surface of the workpiece will hinder the wetting of the solder on the surface of the workpiece, thereby affecting the quality of brazing. The melting point of the oxide film on the aluminum alloy surface is very high, and at a brazing temperature of 270°C, the thickness of the oxide film increases sharply than at room temperature, which seriously hinders the wetting and bonding of the brazing filler metal and the base metal. This is also the main reason why it is difficult to repair aluminum alloy after brazing once;

(2) When soldering aluminum alloys, on the surface of the base metal with oxides, the liquid brazing filler metal tends to condense into a spherical shape, which does not wet with the base metal and does not cause seam caulking.

3. System architecture description

The system consists of seven parts: chiller, induction power supply, extension, output unit, positioning tooling, auxiliary parts, and cleaning after welding.

|

| Figure 2 System architecture description |

4. Process flow

Welding power source selection-sensor selection-solder flux selection-tooling positioning design-accessory selection-welding parameter determination-cleaning after welding

4.1 Selection of welding power source

According to the actual size of the radiator, we choose a dedicated all-digital L-DIH-40 model as the welding power source.

|

Figure 3 All-digital L-DIH-40 welding power source |

4.2 Sensor selection

The heat sink is an aluminum component composed of thin sheets, and the difference between the size of the heat sink and the bottom plate is small, but the wall thickness of the single-piece heat sink and the bottom plate are quite different. In the case of absorbing the same energy, the bottom plate generates less heat than the heat sink. When designing the inductor, consider the uniform heating of the bottom plate and the heat sink, that is, reach the brazing temperature at the same time. At the same time, it is necessary to consider the production efficiency of the workpiece in the production process, and the way of putting in and taking out. Combining these two factors, a flat-disc four-turn sensor (ie "mosquito-repellent coil" sensor) was designed.

|

| Figure 4 Welding output terminal |

4.3 Selection of solder additives

(1) The melting point of the solder must be lower than the melting point of the base material;

(2) The solder can be well wetted and flowed on the surface of the base material after melting;

(3) It can be combined with the base metal to form a firm joint;

(4) The composition is stable, non-toxic and harmless.

|

| Figure 5 Solder additives |

4.4 Positioning tooling

Due to the uneven distribution of the magnetic field of the disc inductor, it is necessary to fine-tune the final workpiece position according to the heating state (whether there is an area that heats up too fast);

Need to tighten the workpiece to be welded. Otherwise, when the equipment is working, the position of the workpiece will change due to the electromagnetic force (Lorentz force).

|

| Figure 6 Tooling positioning |

4.5 Selection of accessories

In high frequency induction welding, the induction heating power supply needs to be cooled, and an industrial chiller of corresponding specifications is required. When the customer uses the infrared mode and performs temperature monitoring in real time, a digital infrared thermometer needs to be installed. Our company's infrared temperature measurement When the instrument and the power supply work together, the temperature control accuracy can reach up to 1℃. Our company can provide water chillers, high-frequency brazing customized infrared thermometers.

|  |

| Figure 7 Industrial chiller | Figure 8 Digital infrared thermometer |

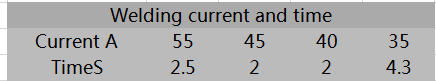

4.6 Determination of welding parameters

After our long-term high-frequency brazing research and a lot of customer experience, we choose the automatic heating mode in this model. The heating current of the automatic heating mode is divided into five sections. In this process, the characteristics of aluminum metal increase with the temperature. High resistance increases, and the Joule effect causes the heating rate to increase during the heating process. This is inconsistent with the welding process summarized by our research. Therefore, we use the method of gradual decrease in current to heat the welding part. In this way, the temperature of the welding part can be increased under the premise of uniform heating, and the workpiece can be prevented from overburning in the high temperature section. Finally, in order to ensure the integrity of the welding process, we set a small current for heat preservation afterwards to ensure that it reaches the penetration standard and has no porosity. And other technological standards.

|  |

| Figure 9 Heating parameter setting | Figure 10 Display of operating parameters |

5. Operation steps

Surface preparation: remove the oxide film and oil stains on the surface of the workpiece

Positioning of the workpiece: the workpiece is positioned, supported, and fixed to ensure that the relative position of the workpiece and the sensor is unchanged during mass production, and the brazing filler metal is made into a ring and added to the part to be welded.

Heating process: using the previously set parameters, the operator only needs to press the start button, the equipment will automatically execute the previously set parameters to accurately weld the workpiece, and stop heating after the welding is completed.

Post-brazing treatment: directly put the workpiece in the water or clean it with other chemicals

6. Electricity consumption calculation and welding consumables consumption

According to the above parameters, the power consumption for brazing 1000 radiators:

0.018125(degree/unit)X1000(unit)=18.125(degree);

According to the above parameters, the amount of solder paste for welding 1000 radiators:

Solder paste coating area: 5 (cm)x4.5 (cm)=22.5 (cm^2)

The amount of solder paste: 1000 (pieces) x0.1 (g/cm^2) x22.5 (cm^2) = 2250 (g) = 2.25 (KG)

7. Summary

This article describes the five aspects of radiator high-frequency induction brazing technology, material welding performance analysis, process flow, operation method, power consumption calculation and welding material consumption, and puts forward a question about the difficulty of induction brazing of aluminum metal. A solution based on all-digital induction heating technology, covering all links before welding, during welding, and after welding. And given detailed and effective data to prove the advantages of high-frequency induction brazing in radiator high-frequency induction brazing.

Scan and follow!

Scan and follow!