Technology Exchange

High frequency brazing of battery cooling system for new energy vehicles

High-frequency welding process of water-cooled plate/water-cooled belt of battery cooling system for new energy vehicles

The domestic auto market will stop growing in 2019, and the growth rate is expected to be zero. But for new energy vehicles, there are still many opportunities. The data shows that before November 2018, the sales of new energy vehicles increased by 68% year-on-year to 1.03 million units, breaking through the 1 million unit mark, which also means the official rise of my country's new energy vehicle market. Xiao Yue, an industry insider who has been engaged in automotive research for a long time, told the Changjiang Business Daily that the sales growth rate of new energy vehicles in 2019 will slow down, but the growth rate is expected to exceed 40% (the above content is quoted from China Economic Net)

Battery technology in new energy vehicles is a core technology, and the quality of the battery has a great impact on the performance of the vehicle. Many car companies want to get a share of the new energy car industry, but due to technical reasons, the risk of entering the market is relatively high, and many car companies can only wait and see. To give a very simple example, the welding problems of water-cooled belts and water-cooled plates commonly used in battery cooling devices of new energy vehicles have plagued a large number of enterprises. The reason for in-depth analysis is not that the current technology level is not up to A large number of companies are discouraged. So is there a low-cost and high-quality welding process? The answer is yes, high-frequency welding is a process with lower cost and better welding quality.

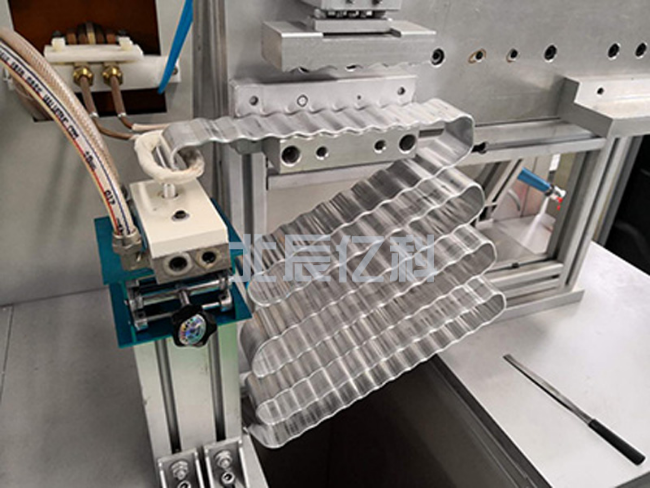

The serpentine water-cooling belt is a commonly used accessory in the power battery cooling system. Its principle is to embed the lithium battery in the groove and add a cooling medium to cool the battery pack.

Lithium batteries are embedded in the grooves of the serpentine water-cooled belt to form the power supply for new energy vehicles

The famous Tesla uses this technology to cool the power battery. The parts of the serpentine tube that need to be welded are the flat tube and the joint, as shown in the figure below (please click on the picture to view the welding video).

High frequency brazing of serpentine water-cooled belt

Since the wall thickness of the flat tube of the serpentine tube is only 0.3mm, it is easy to burn through the base material by artificial flame brazing, and it is also difficult to ensure that the solder temperature rises uniformly and melts to form a weld at the same time. It is difficult to recover the cost of the brazed tunnel furnace without the output of more than 500,000 pieces a year, and the equipment investment of millions of dollars is unacceptable for ordinary enterprises. Considering comprehensively, high-frequency welding is more suitable. Its single-piece operation, small footprint, and low requirements for operators are its major advantages. At the same time, high-frequency welding has higher welding quality, better consistency, and beautiful weld seams are the icing on the cake.

In addition to the serpentine water-cooling belt, the water-cooling plate is also a mainstream power battery cooling device. It is also the most adopted solution by domestic and foreign new energy vehicle companies. (Please click the picture below for the welding video of water-cooled plate faucet)

Water cooling plate

Compared with the water-cooled belt, the water-cooled plate has a larger size and a larger welding position span. It will also lose a lot of heat during the welding heating process. Therefore, it is very difficult to ensure a uniform welding temperature and the solder melts at the same time. Compared with the water-cooled belt, the welding of the water-cooled plate is more difficult, but the effect of using high-frequency welding in optimizing the tooling and adjusting the sensor is quite good. (The picture below shows the welding effect picture of the water-cooled plate)

Scan and follow!

Scan and follow!