Produts

80kw Air-Cooled Medium Frequency Induction Heating Power Supply

Equipment Power: 80kw

Equipment Frequency: 2-10KHZ

Control Mode:Embedded Control Software

Operation Mode:Manual,Automatic,Temperature Control

Delivery Time: 3-20 days after confirming order,detail delivery date should be decided according to production season,order quantity and destination.

Warranty: 12 Months

Online Inquiry

-

-

Equipment introduction

80kw Air-Cooled Medium Frequency Induction Heating Power Supply

Features of Air-Cooled Medium Frequency Induction Heating Power Supply:

1)Using all-digital embedded control software, the heating accuracy is higher;

2)The heating equipment has a transformer with adjustable ratio, which can adapt to a variety of load conditions;

3)The output of the equipment is stable and can work 24 hours a day;

4)The equipment can work in harsh outdoor environments, with strong resistance to impact, corrosion and vibration;

Technical Parameters:

Product Name

Post Weld Heat Treatment Machine

Model

DIH-W-40S

DIH-W-80S DIH-W-120S DIH-W-160S DIH-W-200S Power

40kw

80kw 100kw 120kw 200kw Frequency

2-20khz

Temperature Control

1-5 channels of temperature data acquisition, 1 channel of temperature control

Application of Air-Cooled Induction Heating Power Supply:

Electromechanicalmaintenance industry

Disassembly and installation of large mechanical and electrical equipment, such as the disassembly and hot assembly of largeworkpieces such as bearings, gears, sprockets, counter wheels, couplings, connecting shafts, balance shafts, and roller motoirotors;

Petrochemical industry

Preheating of oil pipelines, thermal coating of pipelines, heating of oil storage tanks, etc..

Preheating before welding, post welding heat treatment, hydrogen elimination treatment

Preheating of pipelines before welding, mold preheating, hydrogen elimination after welding of pipelines, post-weld heattreatment of steel structures, and post-weld heat treatment of boiler main steam pipelines.

Other applications

Air-cooled Induction Heating Power Supply can be used for heating steam generators, heating engineering, drying of industrialproducts, heating of reaction axes, heating of raw materials for chemical production, etc.Preheating of straight welds and fillet welds of steel components in the engineering machinery industry. Preheating of welding of wind power and nuclear power equipment, preheating of welding of pressure vessels, etc.

Case:

Accessories:

High Temperature Mica Wire

Extension cable

Silicone heating wire

Induction heating belt

Thermocouple

Thermocouple compensation wire

Aviation plug

Thermocouple compensation wire

Thermocouple junction box

High temperature alloy cable

Paper recorder

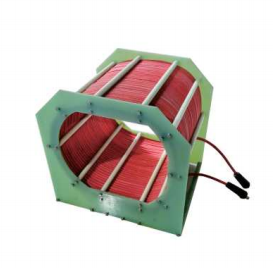

Skeleton coil

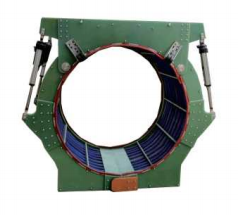

Open and close coil

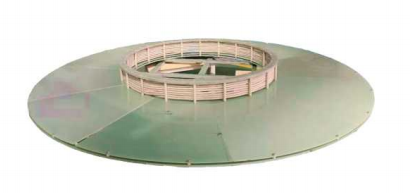

Tooling coil

C-type coil

Heating cord storage cart

Partners:

Tags:

Air-Cooled Intermediate Frequency Machine Induction Heating Machine

Scan and follow!

Scan and follow!